Compound fertilizer production line provided for making powdery compound fertilizer and granular fertilizer. As we all know, compound fertilizer is the fertilizer that contains two or more nutrients. And it has the character of high nutrient content, few subsidiary components and good physical properties. In addition, it plays a very important role in balanced fertilization, improving fertilizer utilization rate and promoting high and stable yield of crops. With the help of compound fertilizer, you can get high-yield and high-efficiency compound fertilizer. In SEEC, there are many kinds of compound fertilizer production line for you to choose. For example, SEEC compound fertilizer production line is divided into 20,000 tons, 30,000 tons and 50,000 tons according to the production capacity. And we can customize the fertilizer production lines with different production capacity for you according to your requirements.

What elements can be used to make compound fertilizer?

Generally speaking, there are many ingredients can be used to make compound fertilizer. These compound fertilizer elements include urea, ammonium chloride, ammonium sulfate, liquid ammonia, monoammonium phosphate, diammonium phosphate, potassium chloride, potassium sulfate, sulfuric acid, synthetic ammonia, urea, ammonium sulfate, phosphoric acid, calcium, calcium magnesium phosphate, nitric acid, some clay fillers and so on. All of these compound fertilizer elements can be used to make compound fertilizer. With these compound fertilizer raw materials, you can get the compound fertilizer that you want. In addition, if you still have some special requirements, please contact with us, we will try our best to meet your requirements.

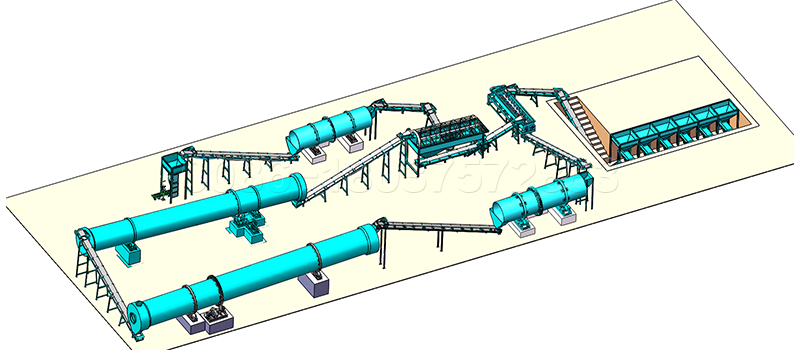

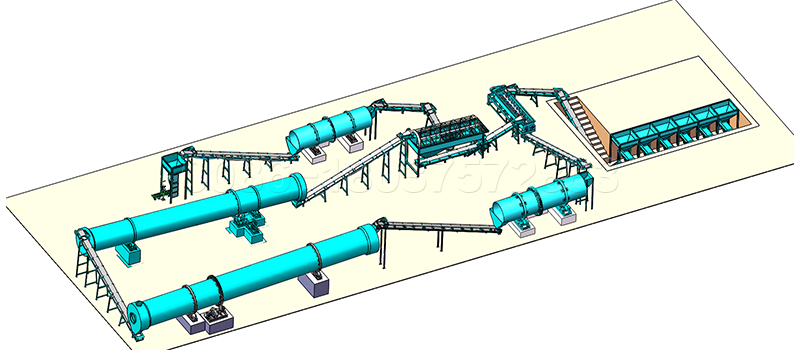

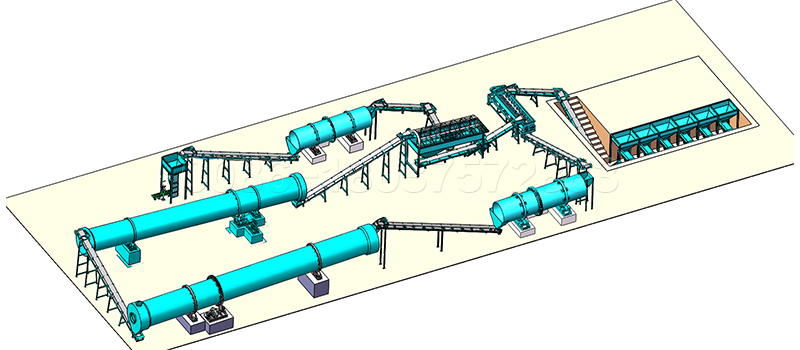

The whole compound fertilizer production line

A complete compound fertilizer production line includes five steps at least. If you want to get compound fertilizer, you’d better know these processes. That can help you make a clear compound fertilizer production project report.

- Crushing. Maybe the raw material you get is lumpy, and lumpy fertilizer can’t be applying to the farmland directly. So, you should use a lumpy fertilizer crushing machine to help you make powdery compound fertilizer. According to the compound fertilizer raw material have high hardness, we have cage crusher and chain crusher can crush the fertilizer raw material.

- Mixing. After the process of crushing, you can get powdery compound fertilizer raw material. Then you need to mix these different fertilizer raw materials together. And you can use a fertilizer mixing machine to help you.

- Granulating. Then you can come to the granulation process. As we all know, most of the compound fertilizers we see are granular, because granular fertilizers are easier to transport and store. So, you can depend on a compound fertilizer granulation equipment to make it.

- Screening. Because there are some unqualified fertilizer pellets left. Thus, you need to sift these unqualified granules out. You should use a fertilizer screening machine to do that.

- Packing. For getting the compound fertilizer as soon as possible, you’d better use an automatic packing scale to pack the finished fertilizer.

That is the complete compound fertilizer production line. With these fertilizer making processes, you can get the compound fertilizer what you want. And compared with organic fertilizer production line, compound fertilizer production line is easier than it. Because you need to use more organic fertilizer production equipment.

Small-scale compound fertilizer production line provided by SEEC heavy industry technology

In SEEC, we still have small-scale compound fertilizer production line for make small yield compound fertilizer. We not only have the compound fertilizer production line with the production capacity of 30t/h, but also have the fertilizer production line with 0.02t/h. Except that, we also have the fertilizer production line with other production capacity. Therefore, you can choose the fertilizer production line that you want. In your compound fertilizer production line, you can equip with some small yield compound fertilizer making machines. To be honest, the reason why our customer choose mini compound fertilizer production line is they have limited production sites. Thus, we will suggest them to choose bucket elevator instead of mobile belt conveyor to save more production space.

How can you make NPK compound fertilizer granules?

Generally speaking, the process of granulating is the main process of making granular compound fertilizer. And how can you get NPK compound fertilizer granules in the NPK fertilizer production line? In fact, you should use NPK compound fertilizer granulation equipment to help you. In SEEC, we have many compound fertilizer granules making machine, such as, double roller extrusion pelletizer, rotary drum granulator machine, disk pellets making machine. If you want to get compound fertilizer pellets, you just need to switch on the compound fertilizer pelletizer, then put the powdery compound fertilizer inside. After a few minutes, then you can get the granular compound fertilizer.

In addition to this, we can also help you make NPK fertilizer plant design. And this allows your fertilizer plant to operate in a reasonable manner.

Compound fertilizer machinery equipment should be used in your compound fertilizer production line

We all know that you should use some compound fertilizer making machines in the compound fertilizer production line. But do you know how many compound fertilizer machinery equipment should be used? There are two different production method, and different fertilizer making method have different fertilizer making machine.

If you adopt wet type granulation, you should use fertilizer crushing machine, compound fertilizer mixer, disk granulator, rotary drum drying machine, rotary drum cooling machine, granular fertilizer rotary drum screening machine, automatic packing scale in your compound fertilizer production process.

And if you adopt dry type granulation, you’d better use fertilizer crushing machine, compound fertilizer mixing machine, double roller extrusion granulator machine, rotary drum screening machine and automatic packing scale in your compound fertilizer production line.

How can you get NPK compound fertilizer?

NPK Compound Fertilizer Granulation Equipment

As a compound fertilizer manufacturer, what should you do?

In order to make compound fertilizer, you should know these things as follows. Here are the preparatory works for a compound fertilizer production line.

- Making a clear compound fertilizer production report. Before you start a fertilizer production line, you need make a clear production report. That can help you have a clear fertilizer production process. For example, you should do a market research to get information about the compound fertilizer factories around you.

- Finding a stable compound fertilizer raw material supplier. As we all know, if you want to get compound fertilizer pellets, you had better prepare for the compound fertilizer raw material first. That is important part of the fertilizer production line. Thus, it’s necessary for you to find a stable compound fertilizer raw material.

- Machine. As mentioned above, compound fertilizer machinery equipment

- Finding a suitable compound fertilizer production site. Generally speaking, there are many factors you need to consider, such as, the budget, electric power, traffic, water source and so on.

If you can deal with these things well, then you can set up a qualified compound fertilizer plant.