In nowadays, NPK fertilizer became the hot sale fertilizer. And many farmers choose NPK compound fertilizer for their crops and plants. Because lack of nutrients in the soil can cause food production to decrease. With this problem, farmers will apply NPK fertilizer to their farmland. Because NPK fertilizer can supplement the lack of nutrients in the soil. And with this phenomenon, there are many fertilizer manufacturers starting NPK fertilizer business and want to build a NPK compound fertilizer plant. Many of our customers choose SEEC as their NPK fertilizer plant designer. In NPK manufacturing industry, you had better use suitable NPK fertilizer making equipment to make it. In SEEC, we will recommend the high efficiency NPK fertilizer production facilities you need.

What is NPK compound fertilizer?

Many people want to make NPK compound fertilizer, because it has beneficial elements. But do you know what is NPK compound fertilizer?

Generally speaking, Plant nutrients are classified as either primary nutrients, secondary nutrients, or micronutrients. NPK fertilizer is a complex fertilizer containing primary of the three primary nutrients required for healthy plant growth. These are nitrogen(N), phosphorus(P) and potassium(K). And these three most important nutrients, without any one of which plants could not survive, are referred to as the primary macronutrients. Thus, each of the primary nutrients is essential in plant nutrition, serving a critical role in the growth, development, and reproduction of the plant. There is no doubt that these elements will help you get more fertile soil.

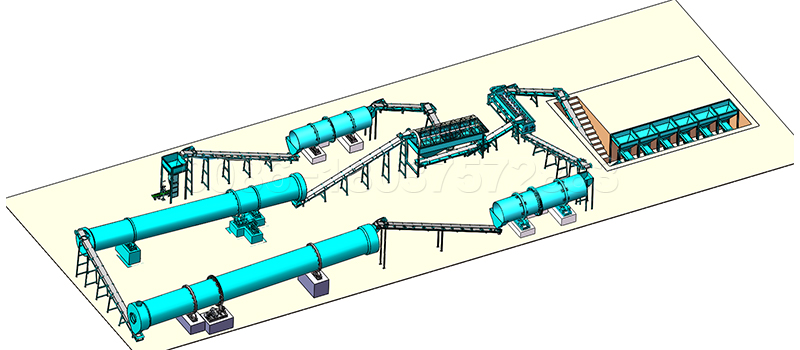

How many NPK fertilizer processing machinery do you need?

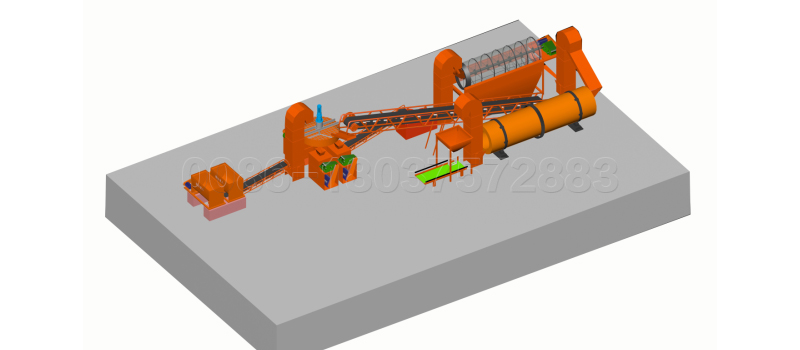

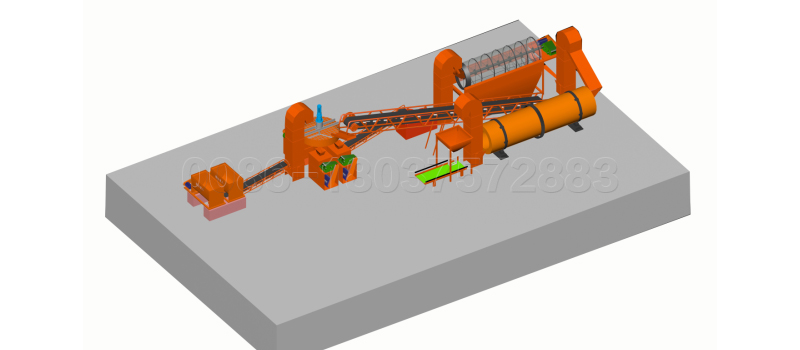

NPK fertilizer production equipment is the most important condition to make NPK fertilizer. But how many NPK fertilizer processing machinery should be used in your NPK fertilizer production plant? Here are the facilities you need to use.

Firstly, the first machine you need to use is the batching machine. Then fertilizer mixing machine, NPK fertilizer pelletizer, drying machine, cooling machine, screening machine and automatic packing machine also should be used. You need to use these compound fertilizer machines in sequence. With these NPK fertilizer machines, you can get the NPK fertilizer in a very short time. And the quality of fertilizer will be better than others.

How is NPK fertilizer made?

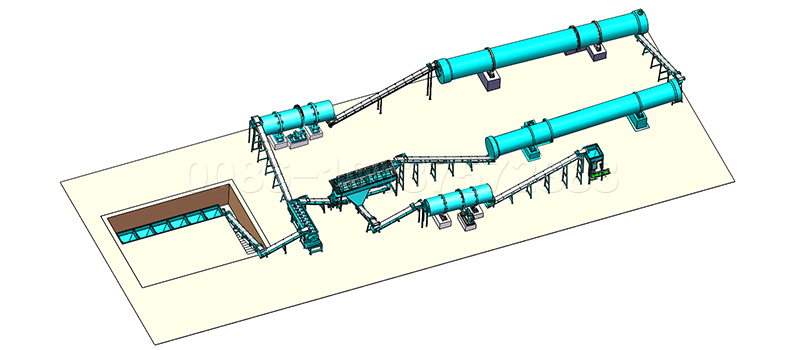

That is the NPK fertilizer making process. If you want to make NPK compound fertilizer, you need to go through the following steps carefully. Here are the NPK fertilizer production processes.

Batching. In fact, the NPK fertilizer raw material should be prepared in a certain proportion. Then the NPK fertilizers can do their best. You can use SEEC batching machine to achieve this goal.

Mixing. In order to mix the powdery NPK fertilizer raw material evenly. You had better use NPK fertilizer mixing machine to do this.

Granulating. To be honest, NPK fertilizer have different forms, but granular fertilizer is the most common. You should use NPK compound fertilizer granulator to make NPK fertilizer pellets.

Drying and cooling. There are two kind of NPK fertilizer making methods. If you adopt wet type granulation, you should use drying machine and cooling machine to remove the excess moisture.

Screening. The next process is screen. Because there are some unqualified fertilizer granules after the process of granulating. You should use NPK fertilizer screening machine to screen them out.

Packing. This is the final step in the NPK compound fertilizer production line. Automatic packing machine can help you pack the NPK fertilizer pellets.

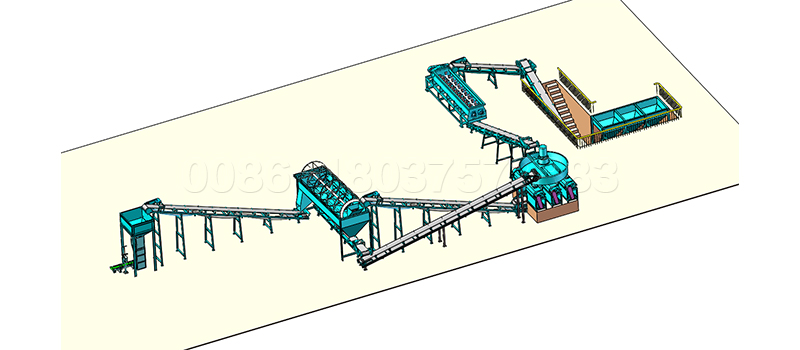

What kind of NPK fertilizer production technology should you use?

In SEEC, we have two kind of NPK fertilizer production technology to make NPK fertilizer granules. That is wet type granulation and dry type granulation. Most of our customers choose dry granulating machine to make fertilizer pellets. Because with the dry granulating machine, the hardness of fertilizer particles will be higher than wet granulating machine. So, we call this NPK fertilizer as dry type or non-drying compound fertilizer production line. The reason why we call this line as dry type or non-drying compound fertilizer production line is because roll extrusion technology is adopted. In fertilizer granulation process, double roller extrusion granulator machine is used, therefore, the moisture content of raw materials should be under 6% and don’t need adding water in the whole granulation procedure. That is the special character of extrusion technology. Thus, it will be better by using dry granulating machine.

Two roller extrusion pellet mill for sale

- Model: SEECWJ-2T(can be customized)

- Power(kw): Granule diameter≤4.5m: 22

- Granule diameter>4.5m: 30

- Granule diameter(mm): 3-10

- Roller sheet size(mm): 185×300

- Dimensions(mm): 1630×850×1650

What are the requirements of raw material for setting up a complex NPK fertilizer plant?

As we all know, there are many NPK fertilizer raw materials can be used to make NPK fertilizer. Choosing suitable NPK fertilizer material is important for you to make it. You should pay attention to this question.

Thus, what kind of NPK fertilizer raw material should you use? Here are the NPK fertilizer raw materials that you can use to make NPK fertilizer. Urea, ammonium bicarbonate, ammonium chloride, ammonium sulfate, ammonium nitrate, liquid ammonia is usually used as raw materials for nitrogen fertilizer. The main raw materials for phosphate fertilizer are superphosphate, superphosphate, monoammonium phosphate, diammonium phosphate, phosphate nitrate. The main raw materials for potash fertilizer are potassium sulfate and potassium chloride. These are what you can use to make NPK fertilizer.

For setting up a NPK granulation plant, what do you need to prepare for your NPK granulation plant?

If you want to set up a granulated NPK compound fertilizer plant, you need to consider many factors. Because it is not easy to make compound fertilizer pellets. Here are the factors that you should consider.

The raw material. For getting high efficiency NPK fertilizer, you need to prepare the NPK fertilizer raw material first. That means reliable supplier is important. The main NPK fertilizer raw material includes urea, superphosphate and potassium sulfate.

NPK fertilizer making machine. As we all know, if you want to get granulated NPK fertilizer, you need to rely on some NPK fertilizer production machines. And the most important NPK fertilizer granulation equipment is NPK compound fertilizer granulator.

Experienced workers. To be honest, you have to hair some workers to help you make NPK fertilizer pellets. You had better choose the experiences workers as your worker. But it doesn’t matter if you don’t have experienced workers, because our machines are easy to operate and master.

Reasonable NPK fertilizer granulation plant design project. Before you set up NPK granulation plant, you should have a reasonable NPK fertilizer granulation plant design project. That can guide you to a right place. SEEC can help you design a suitable NPK fertilizer plant design project for you.