What’s the working power of the double roller granulators with different capacities?

Are you looking for the compound fertilizer granulator with the capacities you want? In SEEC heavy industry technology, we have different double roller extrusion granulators with different capacities based on the working powers. In addition, we provide exact technical parameters of double roller fertilizer granulator for you.

- The capacity is 1t/h. If you choose the production capacity of fertilizer pelletizer is 1t/h, then the power of the granulator is 11KW or 15KW.

- The Production capacity is 2t/h. And if you choose the production capacity of double roller extrusion granulator is 2t/h, the power of the granulator is 22KW or 30KW. Furthermore, you can choose the granule diameter with 3-10mm.

- The capacity is 3t/h. SEEC double roller granulator also have the capacity is 3t/h. With the capacity is 3t/h, the power of the compound fertilizer granulator is 37kw-45kw.

With these different technical parameters, you can choose the suitable fertilizer double roller extrusion granulating machine for your needs. Furthermore, we can customize the fertilizer pellet making machines for customers’ requirements.

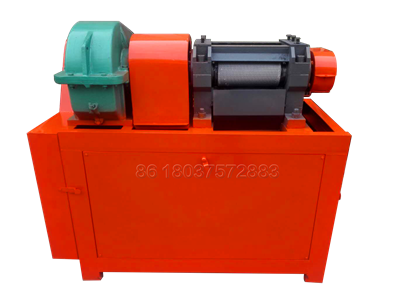

Granular fertilizer double roller extrusion pelletizer

- Model: SEECWJ-1T(can be customized)

- Power(kw): Granule diameter≤4.5m: 11

- Granule diameter>4.5m: 15

- Granule diameter(mm): 3-10

- Roller sheet size(mm): 150×220

- Dimensions(mm): 1450×800×1450

How does SEEC double roller granulator makes granular fertilizer step by step?

How does this double roller granulation machine make granular fertilizers? It needs different parts of the roller granulator work together. There are mainly five steps turning materials into granular with this double roller compound granulating equipment.

- Firstly, you need put the mixed npk or compound fertilizer materials on the belt conveyor, then the powdery raw material will enter the double roller extrusion granulator.

- The material is forced between the two rollers below for extrusion, and the two rollers rotate relative to each other.

- Under the strong extrusion pressure, the delivered materials become a cake shape with a stick mold, and the cake shape bar enters the crushing workshop.

- The crushed materials are broken by the broken axis, and are screened through the screen below the crushing chamber.

- Qualified particles are sent to the outside through the air. And the sifted powder material will be sent back to the raw material warehouse for the second roll.

After these five steps, you will get the compound or npk fertilizer pellets.

1.5T Double roller granulator for sale

- Model: SEECWJ-1.5T(can be customized)

- Power(kw): Granule diameter≤4.5m: 18.5

- Granule diameter>4.5m: 22

- Granule diameter(mm): 3-10

- Roller sheet size(mm): 150×300

- Dimensions(mm): 1450×850×1500

What should you pay attention to when you operate the double roller fertilizer press granulator?

Do you want to extend the life of your double roller fertilizer granulator? If the answer is “yes”, then here are a few things you need to know. That can make your double roller granulator work better.

- Double roller extrusion machine should start without load. It is strictly prohibited to start with fertilizer materials.

- You can’t mix iron into the material. That can break the roller.

- You should grease the gears before starting the machine.

- You also need to grease the chain and sprocket every 7 days.

- The bearing block is replaced with new yellow dry calcium ester oil every three months.

- You should add the gear oil before using the reducer, and then can be used in production. In addition, you should every four months to replace the gear oil.

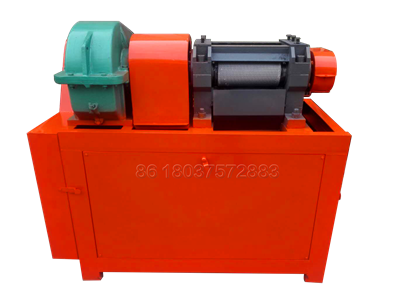

SEEC roller extrusion granulator for sale

- Model: SEECWJ-2T(can be customized)

- Power(kw): Granule diameter≤4.5m: 22

- Granule diameter>4.5m: 30

- Granule diameter(mm): 3-10

- Roller sheet size(mm): 185×300

- Dimensions(mm): 1630×850×1650

What facilities are needed in SEEC double roller granulating production line?

In SEEC heavy industry technology, we not only provide double roller granulator for you, but also provide a complete double roller granulating production line. The whole granulating production line include batching machine, mixer, granulator, dryer, cooler, screening machine and packing machine.

- Static batching machine. Before you start your fertilizer production line, you need to put your compound fertilizer raw material into the static batching machine. You know, you should prepare the raw materials in a certain proportion before production.

- Fertilizer mixer. Then the fertilizer powder can go into the mixing process. The function of the fertiliser mixer is to mix the powdery compound fertilizer well.

- Double roller granulator. Next the fertilizer will enter the granulating process. As mentioned above, the double roller granulator and npk compound fertilizer pelletizer will help you to get fertilizer pellets.

- Rotary drum cooling machine. SEEC rotary drum cooling machine will make the fertilizer cool and easy to package.

- Rotary screen machine. Screening is the obbligato part of the double roller granulating production line. You can get the qualified fertilizer particles by using rotary screen machine. And unqualified fertilizer pellets will be screen out.

- Double bucket automatic Packing scale. The last step is packing. SEEC double bucket automatic packing machine can help you a lot.

What makes us special compared to other makers of double roller press fertilizer machine?

- Patented products manufacturer: SEEC double roller granulator is the patented product of our company.

- Multi-application fields: The double roller extrusion granulator is the most widely used granulator in compound fertilizer granulator. So you can use the fertilizer granulator in many places. Such as, npk fertilizer, bentonite fertilizer, tombarthite, ammonium bicarbonate, etc.

- Leading design technology: Then the design of the double roller extrusion granulator is very reasonable, very practical, low energy consumption. And at room temperature, you can get the fertilizer pellets continuously without drying.

- Customized manufacturing service: We can produce the ball and socket on the roller according to the size and shape of the customer’s demand. At present, we have made ball shape, pillow shape, semicircle shape, bar shape, pill shape, walnut shape, flat ball, square bar shape and so on. Most of our clients use flat balls.

- In time after sale service: In addition, another reason customer chooses us is that our good after-sales service. You don’t need to worry about the quality problem after you buy it.

- Highly working efficiency: And SEEC double roller granulator has the character of the short granulation process, low energy consumption and large output. Dry powder can be directly granulated without subsequent drying process, which is more conducive to the connection and transformation of existing production processes. Furthermore, the granule strength is high.

Compound fertilizer roller pellet mill

- Model: SEECWJ-3T(can be customized)

- Power(kw): Granule diameter≤4.5m: 37

- Granule diameter>4.5m: 45

- Granule diameter(mm): 3-10

- Roller sheet size(mm): 300×300

- Dimensions(mm): 1850×1100×2050

Can I make chicken manure pellet fertilizer with your fertilizer double roller extrusion granulating machine?

Some people want to know whether the double roll fertilizer machine can produce chicken manure fertilizer pellets. This granulator is different from a manure granulator. Double roller granulator is the key equipment for compound fertilizer granulation. And it can also make organic fertilizer. But if you want to get the best organic fertilizer pellets, you should use professional organic fertilizer production equipment-new type organic fertilizer granulator or chicken manure pelleting machine. SEEC new type organic fertilizer granulator machine can handle all kinds of organic raw material. Such as cow manure, horse poop, vermicompost, sheep dung, etc. So no matter what organic raw material you have, SEEC organic fertilizer pellet making machine can help you. If you want to make compound fertilizer pellets, you can use this double roller press fertilizer machine.